- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Materials Testing EquipmentContact Us Today! 800-444-1508

Search

Asphalt Binder Testing

Asphalt binder testing is a key step to ensure proper mix design and hot mix asphalt production. Gilson has everything you need to perform design and QC/QA tests for viscosity, short and long-term aging of binder, shear, and flexural strength, and much more.

Our versatile line includes advanced equipment that will allow remote, web-based monitoring and control from anywhere in the world.

- Rolling Thin Film Ovens feature model options with advanced or basic controls to effectively measure the short-term aging effects of heat and air on asphalt binder.

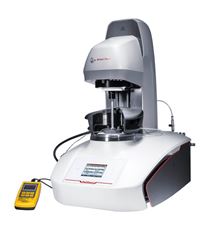

- Anton Paar Dynamic Shear Rheometers offer reliable performance in everyday, routine testing, and quality control in asphalt production facilities. They perform exceptionally well in classifying SHRP/Superpave PG binders. The SmartPave ll model fully complies with ASTM and AASHTO temperature control requirements. Both units are supplied with RheoCompass™ Software.

- Viscosity Testing products are used when evaluating basic binder properties.

- ATS Bending Beam Rheometers are innovative units that accurately predict low-temperature thermal cracking of asphalt pavements by determining flexural creep stiffness of asphalt binder.

- ATS Pressure Aging Vessel is a state-of-the-art, stainless steel-constructed model that simulates long-term oxidative aging of asphalt binder.

- ATS Vacuum Degassing Oven is an easy-to-operate touch-screen unit for degassing pressure aged binder samples to meet ASTM and AASHTO standards.

- Pyrolytic Oven provides a safe automated method for solvent-free cleaning of lab equipment and glassware to remove asphalt and other organic residues.

- Universal Penetrometers are direct-reading precision instruments for bituminous materials. They can also be used to test waxes, greases, foods, and pharmaceuticals.

- Flash Point Testers determine flash and fire points of flammable liquids.

- Softening Point Ring and Ball Apparatus is a traditional method to measure the softening point of asphalt, coal tar pitch, and other viscoelastic bitumen.

- Melting Pots make it easy to dispense asphalt binder for laboratory and mix design testing.

- Ductility Tester, Temperature-Controlled measures elongation of binder specimens before failure. A heating and cooling circulator assures complete temperature control.

Recently viewed products