- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Materials Testing EquipmentContact Us Today! 800-444-1508

Search

Laboratory Grinding Mills

Grinding and milling products are used to process or test materials that are generally tough and fibrous, such as plastics, rubber, and plant products not easily reduced by standard crushers and pulverizers. Grinding and cutting mills can be used for various laboratory applications, such as reducing sample size, mixing or homogenizing pastes or emulsions, and performing materials research.

- Ball Mills are available in Benchtop models. Ball (or Jar) Mills are capable of grinding materials very fine. A wide selection of grinding media is available for the efficient reduction of various material types. Optional accessories can be selected to enhance wear-resistance, reduce contamination, and optimize operation.

- Cutting Mills reduce the sample size of soft to medium-hard and fibrous materials through cutting and shearing action. Standard or large models are available, and units can be configured with a variety of accessories to match laboratory cutting needs, including cutting tool sets, sieve inserts, funnels, collecting vessels, and more.

- Ball-Pan Hardness Test is used to determine the degradation resistance of activated carbon.

- Hardgrove Grindability Tester used to measure the relative ease of pulverization of coals according to ASTM D409. The durable Hardgrove Grindability Tester offers reliability and low-maintenance operation.

- Fritsch Knife Mill is fitted with four blades and can process moist, oily, fatty, dry, soft, medium-hard, and fibrous samples. Variable speed settings of 2,000–10,000 rpm with a 14,000rpm turbo function result in extremely fast mixing, homogenizing, and milling operations.

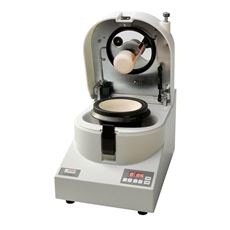

- Mortar Grinder is an all-purpose grinding machine that uses rotational pressure and friction to grind medium-hard, soft, brittle, fibrous, moist, and temperature-sensitive materials. Mortar bowls and grinding sets are available in a variety of materials and downward pestle pressure can be exactly adjusted for reproducible results.

- Fritsch Variable Speed Rotor Mill grinds soft to medium-hard, brittle, fibrous, or temperature-sensitive samples through impact and shearing. The motor features variable speed settings between 6,000–20,000rpm. Final fineness is 40μm depending on the chosen sieve ring, available with trapezoidal, square, or round perforations ranging in size from 0.08–6mm.

- Fritsch Cross Beater Mill performs pre-crushing and fine grinding of medium-hard, brittle, and softer materials, and reduces samples by impact, friction, and shearing forces. Final fineness is 120μm–10mm depending on the material and bottom sieve insert with trapezoidal or round openings ranging in size from 0.12–10mm. Stainless steel and cast iron models are available.