- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Automatic Concrete Compression Machines

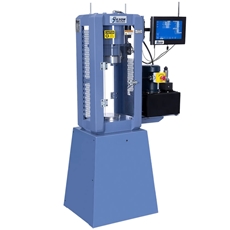

Gilson Automatic Concrete Compression Machines and Rigid Frame Automatic Concrete Compression Machines perform complete strength tests for concrete cylinders, beams, cubes, cores, and other sample types, with minimal operator input. Operator interaction is only necessary for sample preparation and positioning, and for removal of samples after test completion. A single selection on the touchscreen controller initiates the automated test cycle.

Rigid Frame Automatic Concrete Compression Machines are designed with the same automated controller and hydraulic loading system as the Automatic machines but are built with highly rigid load frames to withstand heavy daily testing demands and frequent testing of high-strength concrete mixes.

250,000lbf Automatic Concrete Compression Machines

300,000lbf Rigid Frame Series Automatic Concrete Compression Machines

325,000lbf Automatic Concrete Compression Machines

400,000lbf Rigid Frame Automatic Concrete Compression Machines

450,000lbf Automatic Concrete Compression Machines

500,000lbf Rigid Frame Automatic Concrete Compression Machines

650,000lbf Automatic Concrete Compression Machines

450,000lbf Automatic Compression Machines for Single Masonry Block

500,000lbf Automatic Compression Machines for a Two Block in Prism Sample

Gilson Guardian Cloud Sharing Application

The Automatic controllers are programmed to follow the specification requirements of the selected test for specimen contact, pre-loading, rate of load, break detection, data acquisition, and return of the piston to the home position. Variations in load rates and applications are eliminated, ensuring accurate, repeatable, and documented results that strictly conform to ASTM and AASHTO test methods. Automated testing and documentation of results also lead to higher rates of productivity with fewer errors.

| Test Type | Test Standards | Model Number | Total Capacity lbf (kN) | Maximum psi (kPa) w/6x12 Cylinder | Daylight Opening, in, WxH | Dimensions, in, WxDxH, | |

|---|---|---|---|---|---|---|---|

| ASTM | AASHTO | ||||||

| Automatic Series | |||||||

| Compression, Flexural, & Splitting | C39, C78, C109, C293, C496, C1019 | T 22, T 97, T 177, T 106, T 198 | AC-250 | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.625 | 30x17x58 |

| AC-325 | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 33x17x58 | |||

| AC-450 | 450,000 (2,002) | 12,700 (87,567) | 9.5x19.125 | 34x24x60 | |||

| AC-650 | 650,000 (2,891) | 18,400 (128,868) | 11x19.125 | 35x24x62 | |||

| Compression, Flexural, Splitting, & Modulus of Elasticity | C39, C78, C109, C293, C496, C469, C1019 | AC-250M | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.625 | 30x17x58 | |

| AC-325M | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 33x17x58 | |||

| AC-450M | 450,000 (2,002) | 12,700 (87,567) | 9.5x19.125 | 34x24x60 | |||

| AC-650M | 650,000 (2,891) | 18,400 (128,868) | 11x19.125 | 35x24x62 | |||

| Compression, Flexural, Splitting, Modulus of Elasticity, & Poisson's Ratio | AC-250MR | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.625 | 30x17x58 | ||

| AC-325MR | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 33x17x58 | |||

| AC-450MR | 450,000 (2,002) | 12,700 (87,567) | 9.5x19.125 | 34x24x60 | |||

| AC-650MR | 650,000 (2,891) | 18,400 (128,868) | 11x19.125 | 35x24x62 | |||

| Rigid Frame (RF) Automatic Series | |||||||

| Compression, Flexural, & Splitting | C39, C78, C109, C293, C496, C1019 | T 22, T 97, T 177, T 106, T 198 | AC-300 | 300,000 (1,334) | 8,500 (58,608) | 10x19 | 32x19x57 |

| AC-400 | 400,000 (1,779) | 11,300 (77,914) | 11x19 | 33x19x61 | |||

| AC-500 | 500,000 (2,224) | 14,100 (97,220) | 12x19 | 35x20x60 | |||

| Compression, Flexural, Splitting, & Modulus of Elasticity | C39, C78, C109, C293, C496, C469, C1019 | AC-300M | 300,000 (1,334) | 8,500 (58,608) | 10x19 | 32x19x57 | |

| AC-400M | 400,000 (1,779) | 11,300 (77,914) | 11x19 | 33x19x61 | |||

| AC-500M | 500,000 (2,224) | 14,100 (97,220) | 12x19 | 35x20x60 | |||

| Compression, Flexural, Splitting, Modulus of Elasticity, & Poisson's Ratio | AC-300MR | 300,000 (1,334) | 8,500 (58,608) | 10x19 | 32x19x57 | ||

| AC-400MR | 400,000 (1,779) | 11,300 (77,914) | 11x19 | 33x19x61 | |||

| AC-500MR | 500,000 (2,224) | 14,100 (97,220) | 12x19 | 35x20x60 | |||

| Masonry Block Compression | C140 C1314 | — | AC-401 | 450,000 (2,002) | — | 14x19 | 34x22x62 |

| AC-502 | 500,000 (2,224) | — | 14x23.875 | 35x23x66 | |||

Sample type, test method, entry of specimen data, and test parameters are selected on the Windows-based touchscreen controller. Force, stress, and rate of load are displayed continuously, with options for graphing. The quiet and energy-efficient automated drive system regulates load rate and applied force by feedback during sample loading.

USB and LAN ports, along with Wi-Fi capability, allow easy data collection via flash drive or transfer to the user’s PC or network for reporting of results. Test data can be printed individually or transferred in summary form. Testing laboratory, sample ID, and client information are entered and stored for improved accuracy in reporting and distribution.

The integrated electric motor and hydraulic pump system operate at variable speeds depending on loading demands to achieve and maintain required pressures. This energy-efficient configuration reduces heat build-up, extends the surface life of the hydraulic components, and is noticeably quieter. Rugged welded steel frames exceed ACI 363 requirements for system rigidity, and top-mounted pistons avoid wear from accumulated test debris.

Safety features include a large emergency stop button, a hydraulic relief valve to prevent loading beyond machine capacity, and a limit switch that stops the piston from advancing beyond its limit. Hinged fragment guard doors are made from clear Lexan® to permit the operator to view the sample during testing while still ensuring safety.

All Automatic Compression Machine units are supplied ready for compression strength testing of 6x12in (152x305mm) concrete cylinders with user-supplied unbonded neoprene capping pads and steel retainers. A full suite of Compression Machine Accessories is available for tests of flexural beams, cubes, tensile splitting, and other configurations of cylinders and cores.

In addition to these methods, models that perform ASTM C469 Modulus of Elasticity (MOE) and Poisson’s Ratio on 4 or 6in (101 or 152mm) cylinders feature either one or two LVDT inputs and other factory modifications. Compressometer and Compressometer/ Extensometer testing fixtures for MOE and Poisson’s ratio testing must be purchased separately.

Block compression machines are rigid frame units with an extended opening for testing larger specimens, such as masonry blocks. AC-401 is used to test 8 or 12in (203.2 or 304.8mm) masonry block samples, while AC-502 is used to test single 8 or 12in (203.2 or 304.8mm) block, or two block in prism specimens. Both models arrive ready to test their specified sample types, with the necessary components preinstalled.

Gilson Guardian is the ultimate addition to any Gilson Automatic Concrete Compression Machine. This cloud sharing application allows field samples to be tracked from casting through test completion to ensure full traceability. Specimen and testing data are stored within the mobile app and can be easily shared through the cloud. Multiple subscription tiers are available for a variety of testing needs. The optional QR Code Scanner and Label Printer Kit makes it possible to print and attach a unique QR code to each specimen for easy and efficient specimen management.

Automatic Concrete Compression Machines and Rigid Frame Automatic Concrete Compression Machines are available with power supply options of 110V, 60Hz or 230V, 50Hz electrical systems.