The dynamic cone penetrometer (DCP) is the optimum tool for in-place testing of fine-grained soils, pavement base courses, sub-bases, and soil subgrade layers. The DCP provides fast and cost-effective strength assessments and soil layer depths for pavement designs and foundation bearing surfaces.

What is DCP?

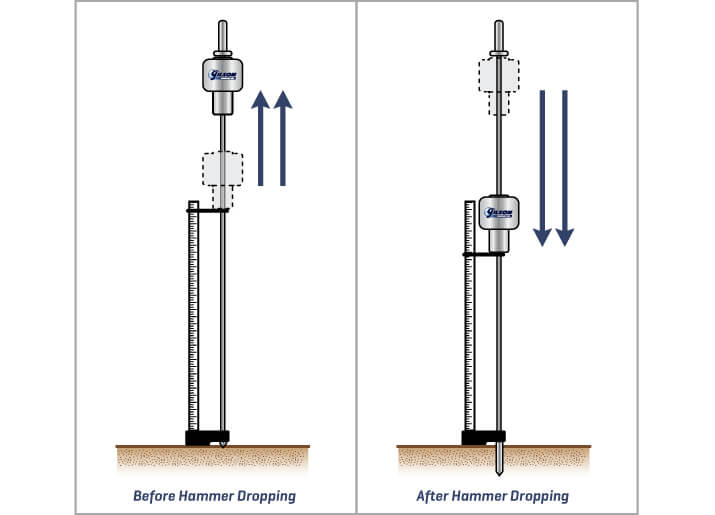

Dynamic cone penetrometers advance a cone-shaped steel tip through the soil matrix using a steel drop-hammer that generates a standard amount of force with each blow. The penetration of the cone with each hammer blow is an indication of the soil stiffness.

A dynamic cone penetrometer is an efficient method to characterize different soil properties. Estimates of shear strength, density, bearing strength, and compaction are made with simple equipment that requires minimal operator training. DCP instruments have evolved with different hammer weights and cone dimensions, so it is essential to match the equipment with the application, but the principles are the same.

History

The soil penetrometer's origin is hard to authenticate, but it is safe to say that its qualitative use has been around for hundreds, if not thousands, of years. The idea is simple; If you can easily force a rod deep into the soil you intend to build on, you will have problems.

Tracking the evolution of the penetrometer as an instrument for quantitative measurement is a little easier. Nicholaus Goldmann developed a ram penetrometer in Germany at the end of the 17th century. A device called a “̈Prϋfstab” was created by Kϋnzel in 1936 and became the Light Penetrometer described in the German Standard DIN 4094 (withdrawn) in 1964. The first modern dynamic cone penetrometer was developed in New Zealand by A. J. Scala. The Scala cone penetrometer was modified and simplified by van Vuuren (1969) in Zimbabwe. A cone penetrometer using two hammer masses was developed in the early 1990s by U.S. Army Corps of Engineers (USACE) scientists at the Waterways Experiment Station in Vicksburg, Mississippi. The dual masses extended the applicable range of the DCP, providing accurate estimates of soil bearing capacities and CBR values from less than 1 to over 100.

Why the DCP?

The dynamic cone penetrometer is rugged and simple to use, manually operated by one or two people, and light enough to pack into remote locations on foot. DCP test results are quick, repeatable, and readily correlate to California Bearing Ratio (CBR) field (but not laboratory) values. ASTM standard D6951 describes how to use dynamic cone penetrometers to measure the strength of undisturbed or compacted soils and estimate their in-situ CBR values for pavement design. DCP testing also identifies and isolates areas of under-compacted soils in engineered fills.

By contrast, CBR, plate-bearing, and other bearing capacity tests performed in the field entail bulky, heavy equipment and are complex and time-consuming. Mechanically or hydraulically driven equipment for standard penetration testing (SPT) or cone penetration testing (CPT) is typically truck or track-mounted, making access to remote areas challenging.

Understanding the DCP Test Equipment

The design of today’s dual-mass dynamic cone penetrometers is standardized to meet current test methods' requirements. The upper drive rod assembly consists of a vertical rod with a top handle, a sliding drop hammer, and an impact anvil. Upper and lower rods are connected with a quick-connect pin. The single-mass or dual-mass drop hammer is lifted manually on the upper drive rod and allowed to free-fall, striking the anvil and driving the cone into the soil. The total free-fall drop height for either hammer mass is 575mm (22.6in). Penetration cones configured for either single-use or multiple uses are mounted on the end of the lower drive rod. The penetrometer cone is 20mm (0.790in) in diameter and tapers at a 60° angle to a point.

Each blow of the drop hammer is counted and measurements of penetration advancement during driving are performed using a vertical scale or measuring rod with 1mm graduations. Most DCP models have a vertical scale with a sliding indicator attached directly to the drive rods as a convenient and practical option. Using a stand-alone detached scale is permissible but can be challenging to manage and position for accurate readings. An electronic recording scale that displays, collects and stores blow count and penetration data is also available. The electronic scale allows one person to operate the DCP while logging accurate blow count and penetration data. Information is stored on a flash drive for correlations to CBR values and soil bearing capacities. Kit configurations that include carrying cases, spare parts, and additional rod extensions for added testing depth are available.

The Dual-Mass Advantage

The “standard” 8kg hammer is a better choice for a wide range of soils with CBR values from 10 to 100. When testing softer soils, a 4.6kg hammer has greater sensitivity and is less physically demanding on the operator. However, it becomes more challenging when the soils are stiff and require twice as many blows for the same penetration.

The versatile dual-mass hammer design features an 8kg drop hammer with a detachable 3.4kg surcharge weight that reduces the total mass to 4.6kg when removed. The dual-mass design ensures the operator is always equipped for efficient testing of a broad spectrum of soil types.

Dual-Mass, Dynamic Cone Penetrometer

A 4.6kg (10.1lb) hammer should be used in weaker materials where the heavier hammer mass would produce too much penetration for each blow. The lighter hammer provides better information for soft or weak soils with CBR values as low as 0.5 and is effective in materials up to a CBR of 80. When calculating results, the blows with the lighter hammer are multiplied by two to calculate the DCP index.

Selecting the Right Penetration Cone

Penetration cones are 20mm (0.79in) in diameter, slightly larger in diameter than the 15.9mm (0.625in) drive rods, so the rods' sidewall friction is minimized during penetration. Multiple-use cones threaded on the end of the drive rod are extracted after each test by driving the hammer upward. The cones must be replaced when they become damaged or worn beyond acceptable tolerances.

It is not unusual for expanding fine-grained soils to squeeze the cones after penetration, making it difficult to extract the apparatus. If these conditions are encountered frequently, disposable cones are available. Disposable cones have the same angles and dimensions but attach to the rod by pushing into a friction adapter. When the test is complete, the drive rod and adapter are easily removed from the hole, while the cone itself is abandoned in place.

The DCP Test

Dynamic cone penetration tests using the dynamic cone penetrometer are not difficult to complete. The upper and lower drive assemblies are connected using a hardened steel pin, and a penetration cone is attached to the lower rod. A multiple-use cone screws onto the rod, or a disposable cone is pushed into the adapter.

When the soil material to be tested lies beneath the pavement, subgrade, or overburden soils, a core drill or auger is used to cut a larger hole to the desired depth. All cuttings and loose materials must be removed from the hole before testing begins.

The assembled DCP is held vertically upright with the cone point seated with its widest dimension flush to the test surface. The initial reading is recorded from the vertical scale. The operator steadies the upper drive rod with one hand on the top handle and lifts the hammer mass with the other hand. The hammer is raised until it lightly contacts the top handle, then released to free-fall onto the anvil. Because of the physical exertion and complexity of operating the drop hammer, counting and recording hammer blows, and measuring penetration, a two-person team makes this test much more manageable.

Penetration readings are taken after a fixed number of hammer blows based on soil stiffness. Typical intervals are one blow for soft material, five blows for typical material, and ten for stiff soils. For each interval, or each change in soil composition or stiffness, penetration is recorded to the nearest 1mm. The average penetration depth resulting from each blow of an 8kg (17.6lb) hammer is expressed as the DCP index. A minimum penetration depth of 25mm (1in) between recorded measurements is recommended. Data from shorter intervals do not always reflect overall conditions and may cause inaccurate results.

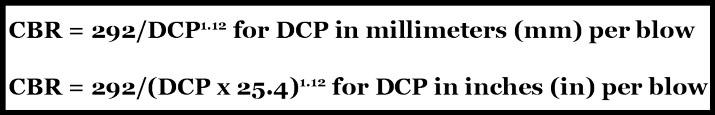

The DCP index is calculated in either metric or English units by dividing the penetration depth between readings by the number of hammer blows. Penetration of 25mm (1in) from 5 hammer blows yields a DCP index of 5mm per blow (0.196in per blow). The ASTM test method provides recommended correlation equations to convert the DCP index to CBR values for most soils:

These equations do not apply to lean clay (CL) soils with CBR values less than ten or fat clay (CH) soils. The test method offers separate equations for these correlations.

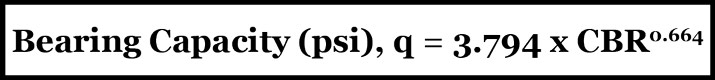

Although the DCP index does not provide a direct correlation to the bearing capacity of soils, this equation from the Portland Cement Association (PCA) uses DCP results converted to CBR values as an estimate:

Other researchers have used correlated CBR values derived from DCP results to estimate soil resilient modulus (Heukelom and Klomp, 1962, and Powell et al., 1984) modulus of subgrade reaction (DOD Manual 3-260-03) and other properties.

The dynamic cone penetrometer is versatile, easy to understand and operate, and provides valuable information on the strength, composition, and layer thickness of soils and aggregates. We hope this blog post has helped you understand this instrument and its applications.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)