For this blog article, we will look at the use of brass for weaving the mesh of laboratory test sieves and how stainless steel has become a more efficient and cost-effective mesh material.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

- Gilson Chat

Gilson Insights

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

The term construction materials testing sounds like a catch-all term for analyzing everything from nails to doorknobs. However, for the civil engineering industry, it has come to mean the characterization of a handful of things by using specific test methods in a construction materials testing laboratory: concrete, aggregates, asphalt, and soils. This blog will take a high-altitude view of what construction materials are, the most important properties to test for, and the right equipment to get the job done.

The dynamic cone penetrometer (DCP) is an efficient tool used to perform soil strength assessments of fine-grained soils, pavement base courses, and more. Learn about the advantages of this tool compared to other penetration testing methods and how to perform penetration tests using the dynamic cone penetrometer.

If you regularly perform asphalt theoretical maximum specific gravity (Rice) tests, the Gilson Rice Shaker is a time-saving tool to have in your lab. Find out why this unit is the key to determining accurate specific gravity determinations for asphalt, aggregates, and soils.

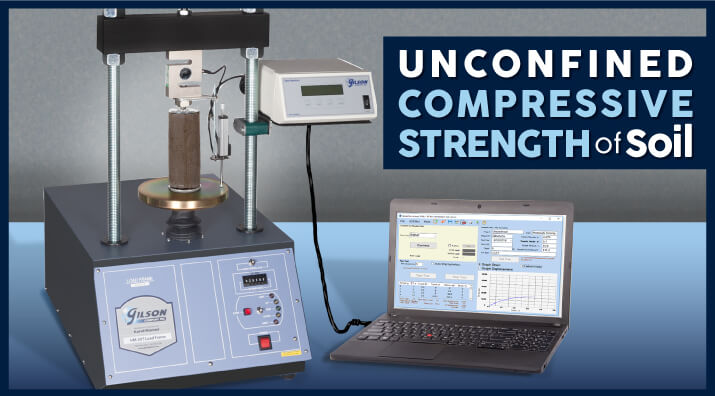

Unconfined compressive strength is a standard geotechnical test performed on cohesive soil samples in construction materials testing laboratories. Straightforward sample preparation and a rapid, uncomplicated procedure makes unconfined compression tests cost-effective when fundamental strength values are adequate for design.

Soil is a natural material and is sometimes employed as a construction material without modification. It is crucial to understand how it performs in its original (in-situ) environment. For this article, we will examine various field tests of soil and the equipment required to perform them.

Some test methods must be performed on the spot to ensure that the best products are being produced or placed following specified procedures. Portable weighing devices are especially important to operate accurately and conveniently in remote locations. In this blog post, we’ll discuss what to look for when choosing one.

Proctor tests of soils are simple to perform and easy to understand. A great way to train inexperienced technicians to follow procedures and pay attention to detail, but also repetitive, tedious, and in some variations, highly physical. Mechanical compactors help, but most have their own issues with accuracy and reliability. This blog article takes a close look at Gilson’s innovative solution to these issues. Our new Mechanical Soil Compactor features an innovative design, quality materials, and the latest technology to generate soil accurate and productive soil moisture/density profiles.

Performing geotechnical and engineering tests on soils in the field is a combination of necessity and practicality. In this two-part series, this first post looks at methods, procedures, and equipment needed for field sampling and visual classification of soils.

With a little thought and planning, you can avoid duplicating the equipment needed to perform many sample preparation tasks. Many ASTM and AASHTO soil tests performed follow similar techniques and use the same or similar equipment to set up samples for your soil testing.

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015