The right Concrete Compression Testing Machine will shape the overall success of your concrete testing. In this guide, we explain the different machines available and how to determine the best option for your lab.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Blog posts tagged with 'Resource Guide'

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

For decades, rotary sifters have served as a reliable and efficient unit for particle sizing operations. Learn about the different types of rotary sifters available and how Gilson's design philosophy helped shape more advanced units that suppress noise and dust.

Knowing how to properly test and verify asphalt binders is essential to understanding how asphalt will react to various climate conditions. This guide covers the methods used to classify asphalt binders and how to perform these tests to ensure optimal pavement performance and longevity.

For this blog article, we will look at the use of brass for weaving the mesh of laboratory test sieves and how stainless steel has become a more efficient and cost-effective mesh material.

The term construction materials testing sounds like a catch-all term for analyzing everything from nails to doorknobs. However, for the civil engineering industry, it has come to mean the characterization of a handful of things by using specific test methods in a construction materials testing laboratory: concrete, aggregates, asphalt, and soils. This blog will take a high-altitude view of what construction materials are, the most important properties to test for, and the right equipment to get the job done.

Verification, calibration, and performance tests all contribute to the accuracy of test sieves. Understanding sieve accuracy will ensure you get the information you need out of your test sieves or screen trays.

Test methods for dry granular materials must be built around the flowability of the material. No sampling, sizing, or handling method can be performed accurately or efficiently if it does not work in harmony with the material's flow properties.

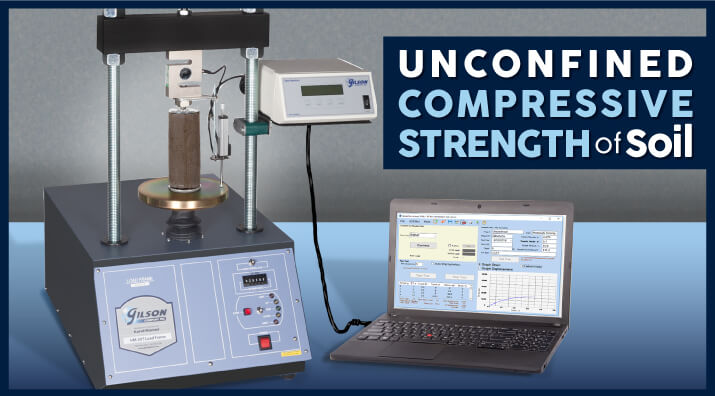

Unconfined compressive strength is a standard geotechnical test performed on cohesive soil samples in construction materials testing laboratories. Straightforward sample preparation and a rapid, uncomplicated procedure makes unconfined compression tests cost-effective when fundamental strength values are adequate for design.

Every stage of sampling, dividing, and testing granular material is affected by its flow properties. Understanding a particular material and the unique factors that impact its flowability increases the efficiency and accuracy of your laboratory testing and can even help control your budget. In this article, we discuss what equipment is best suited for your testing application.

Although Alkali-Silica Reactivity (ASR) has created problems in concrete mixtures for centuries, the mechanism was not understood and documented until the mid-1930s. ASR is now recognized as a significant cause of concrete deterioration anywhere in the world where siliceous aggregates are found. In this blog article, we discuss what ASR is, the effect it has on concrete, prevention, and the equipment to use for testing.

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015