Concrete and asphalt mixtures are composite materials designed and produced based on the volumes of ingredients required. However, producing large amounts of these materials using volumetric measurements is difficult. Batching materials with gravimetric (weight/mass) units is much easier and more efficient.

Accurate relative density (specific gravity) values allow easy conversion of volumes to gravimetric weights for accurate and convenient proportioning. Specific gravity values are also helpful for determining void ratios, detecting anomalies and inclusions in bulk aggregates, and monitoring material quality and consistency.

Relative Density or Specific Gravity?

Relative density and specific gravity are two terms that refer to the same property of materials and are frequently used interchangeably. Either term describes the ratio of a material's density (mass per unit volume) compared to the density of water at 23°C (73.4°F). Because it is a ratio, relative density is a unitless value. Specific gravity is the traditional term, but relative density is considered to be more accurate.

Simple Laboratory Tests Determine Relative Density/Specific Gravity

In the traditional ASTM (C127 and C128) and AASHTO (T 84 and T 85) standard test methods for specific gravity and absorption, the mass of fine or coarse aggregate specimens is determined under three different moisture conditions to calculate specific gravity.

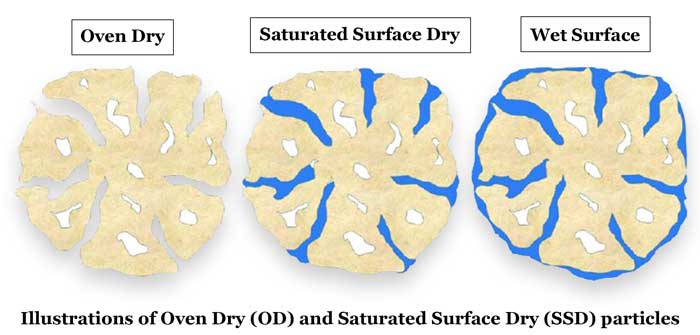

- Oven Dry is just like it sounds. The test specimens are dried in laboratory ovens to a constant mass, as noted in ASTM C566, before being weighed in air. Although aggregate particles may retain traces of moisture internally, water from the exposed pore structure is removed. The moisture content is effectively 0%.

- Saturated, Surface-Dry means that all the accessible pores in the aggregate are filled with water, but there is no water on the surface of individual particles that could contribute to the total water content of the concrete or asphalt mix.

- Submerged in Water is a determination of the mass of a saturated aggregate specimen when suspended in water. The difference between the mass of the sample in air and its mass in water is equal to the mass of the water displaced by the sample.

Types of Specific Gravity

The sample masses measured under different moisture conditions are used to calculate the particular types of relative density values.

- Oven-dried (OD), or bulk relative density, is the ratio of the mass of a unit volume of aggregate, including the empty voids, to an equal volume of water at a given temperature.

- Saturated, Surface-Dry (SSD) relative density is the mass of a unit volume of aggregate, including the weight of the water contained in the voids, to the mass of an equal volume of water.

- Apparent relative density includes only the volume of the aggregate particles, not including the volume of the voids compared to the total aggregate mass.

- Absorption is the percentage difference in mass of an aggregate sample between oven-dry and SSD conditions.

Aggregate Immersion Test: an AASHTO Alternative

The AASHTO T 354 Aggregate Immersion Test is a separate test method that measures the volume displacement of a known aggregate mass using unique volumetric flasks. This test is not discussed in detail here but can be used to determine specific gravity and absorption in fine or coarse aggregates. Test results using this method may require adjustments to align with conventional specific gravity tests. At this writing, the test is being considered by ASTM for inclusion in C127 as an alternate method.

Fine Aggregate Relative Density/Specific Gravity and Absorption

ASTM C128 and AASHTO T 84 tests determine specific gravity and absorption values for mineral aggregates passing a 4.75mm (№ 4) test sieve. The gravimetric test procedure described in this article is the predominant method for this application and uses a Volumetric Flask or Jar Pycnometer for weighing of the immersed sample. An alternative volumetric method uses a LeChatelier Flask with a smaller specimen.

The test begins with soaking an oven-dried bulk sample of approximately 1,000g in water for a specified interval of up to 24 hours. The saturated sample is then manually dried back to a saturated, surface-dry condition using stirring and air circulation methods. Periodic checking with a Cone and Tamp Apparatus is used to verify when the sample reaches the desired SSD condition.

The SSD test for surface moisture is performed by filling the cone to overflowing with the sample material, then lightly compacting it with gentle drops of the tamper for 25 blows. The moisture content is above SSD if the sample retains its shape when removing the cone. If the sample slumps slightly when the cone is lifted, the material has reached a saturated, surface-dry condition.

Approximately 500g of the SSD fine aggregate material is introduced into the pycnometer or volumetric flask partially filled with water. More water is added, filling the pycnometer to about 90% capacity. The pycnometer is then gently agitated manually or mechanically to remove entrapped air without degrading the sample. Gilson's Rice Shaker or the Vibra-Pad Shaker are ideal for mechanical agitation.

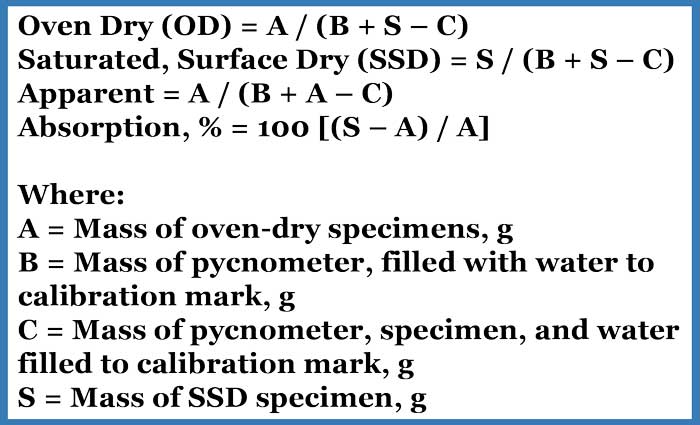

The temperature of the water with the specimen is adjusted to 23.0°C, ±2.0°C, and the water level is adjusted to the calibration mark of the pycnometer. The total mass of the pycnometer, sample, and water is determined and recorded. The entire aggregate sample is then dried and weighed to determine the oven-dry mass. Specific gravity and absorption values are calculated using the sample masses:

Calculating Fine Aggregate Relative Density/Specific Gravity Values

Coarse Aggregate Relative Density/Specific Gravity and Absorption

ASTM C127 and AASHTO T 85 are the most-used standard test methods to measure the specific gravity of normal-weight coarse mineral aggregates retained on a 4.75mm (№ 4) test sieve. Some lightweight aggregates may be tested by extending the required soak times. The method is gravimetric and is calculated from determinations of the aggregate sample mass in oven-dry (OD), saturated, surface-dry SSD, and immersed conditions.

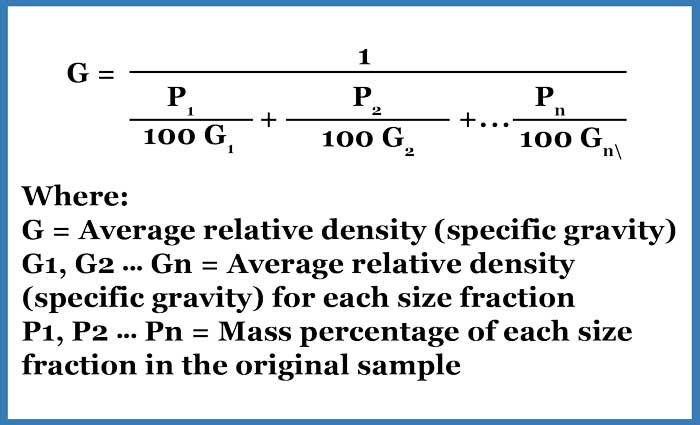

Specific gravity determinations can be made on the full range of particle sizes of the coarse aggregate portion, or on individual size fractions. Average relative density values can be calculated using the test results of each fraction.

Sample preparation of the coarse aggregate specimen consists of dry sieving to determine gradation or to separate size fractions. Minus 4.75mm (№ 4) material is discarded, and the sample is washed manually or using an Aggregate Washer to remove dust and fines.

After oven drying, the test sample is weighed, and the oven-dry mass is recorded. The sample is immersed in water at room temperature for 24 hours, or longer if testing lightweight aggregates. After immersion, surface water is removed from the particles by drying them with an absorbent cloth. Supplementing the drying process with a moving stream of air is permitted. The goal is to bring the sample into a saturated, surface-dry (SSD) condition by removing any visible film of water from the particle surfaces while avoiding moisture loss from the aggregate pores. Weigh the sample at SSD and record the mass.

The next step is to find the mass of the SSD sample immersed in water. The sample is placed in a wire mesh basket and immersed in a container filled with water at 23.0°C, ±2.0°C. The basket hangs from a thin wire or line attached to the weigh-below hook of a suitable digital balance of adequate capacity and readability to accurately weigh the suspended sample.

Laboratories that frequently perform this test method should consider a permanent weighing station that can be set up for efficient suspension weighing of aggregate or other specific gravity samples. Gilson's Specific Gravity Bench can be equipped with a Water Tank, Tank Heater, Tank Circulator, Mesh Basket, or various Density Weighing Cradles for fast and accurate suspended mass determinations.

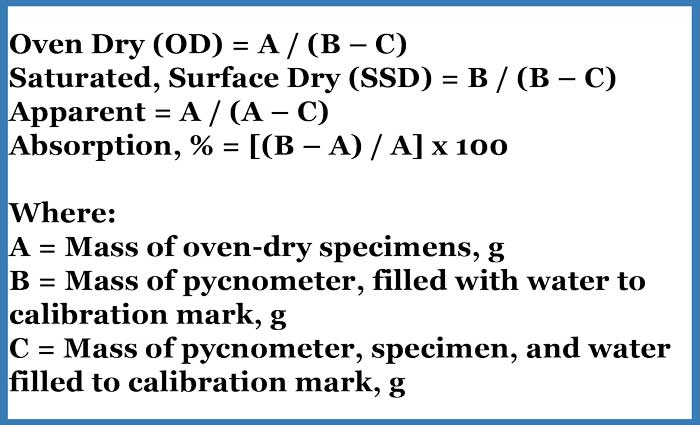

Calculating Coarse Aggregate Relative Density/Specific Gravity Values

To compute an average specific gravity from separate size fractions, the following formula is used in the ASTM or AASHTO standard test methods to calculate any of the specific gravity types:

We hope this discussion of relative density/specific gravity test methods and equipment helps you in preparing your laboratory for performing this critical test. Please contact our testing experts to discuss your specific applications.

Additional Resources

Gilson Videos:

Specifications and References:

- ASTM C127¹, Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate

- ¹Test method was withdrawn in 2024 but is likely to be reinstated soon.

- ASTM C128, Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate

- ASTM C566 Standard Test Method for Total Evaporation Moisture Content of Aggregate by Drying

- AASHTO T 84 Standard Method of Test for Specific Gravity and Absorption of Fine Aggregate

- AASHTO T 85 Standard Method of Test of Specific Gravity and Absorption of Coarse Aggregate

- AASHTO T 354 Standard Method of Test for Specific Gravity and Absorption of Aggregate by Volumetric Immersion Method