In the last installment of our Abrasion Testing series, we wrote about the importance and use of the Micro-Deval Test. An equally important method for abrasion testing is the Los Angeles (L.A.) Abrasion test. In this blog post, we’ll discuss why this type of test matters, redefine abrasion testing, and highlight the benefits of the L.A. Abrasion test.

Why is Abrasion Testing Significant?

Abrasion testing determines the relative quality, toughness, and durability of mineral aggregates subjected to impact and abrasion. Values derived from both the Micro Deval and the L.A. Abrasion tests offer information about the performance of aggregate in use. This testing offers insight into how asphalt and concrete aggregates will stand up to wear and tear over time. It’s also a good indicator of changing properties in an aggregate source as part of quality control or quality assurance program.

What is the L.A. Abrasion Test?

The Los Angeles (L.A.) Abrasion Test is widely used as an indicator of the relative quality of aggregates. It measures the degradation of standard gradings of aggregates when subjected to abrasion and impact in a rotating steel drum with an abrasive charge of steel balls.

ASTM offers two separate standard test methods for aggregate testing with the L.A. abrasion machine:

- ASTM C131 is a procedure for testing aggregates with a maximum size smaller than 1 ½ in (37.5mm).

- ASTM C535 is a test method for coarse aggregates larger than 3/4in (37.5mm).

Note that there is an overlap in permissible sizes, meaning that coarse aggregates with a maximum size between 3/4 and 1 ½ in (19 and 37.5mm) could be tested by either method. AASHTO T 96 is a test method similar to ASTM C131 that also tests aggregates with a maximum size smaller than 1 ½ in (37.5mm).

The drum is fitted with an internal shelf that lifts and drops the charge and sample with each revolution, generating impact forces. After the machine has completed the required rpm, contents are removed and percent loss is measured.

How Does the L.A. Abrasion Test Work?

A sample is prepared by separating into individual size fractions of the required masses.

- The sample of specifically sized aggregates and the abrasive charge is placed in the L.A. Abrasion Machine and rotated at 30-33rpm.

- The sample is removed and washed over a No. 12 (1.70mm) sieve and placed in an oven to dry.

- The percent loss or the difference between the original mass and the final mass is calculated.

- An L.A. Abrasion loss value of 40 indicates that 40% of the original sample mass passed through the sieve after agitation.

What is the Difference Between L.A. Abrasion Test and Micro Deval Test?

The L.A. Abrasion test uses larger dry samples and abrasive charges in a drum with a shelf. The shelf lifts and drops the sample and abrasive charge across the span of the drum, resulting in a very high impact on the aggregate particles. Loss from this test is a result of fracturing and dry grinding of the particles. The Micro-Deval test uses a form of wet grinding of smaller samples in a smooth drum, and loss is a function of wear and attrition.

Still, both tests are considered to be predictive of aggregate toughness and durability although there are difficulties when trying to correlate their results. Suitability often comes down to the degree of acceptance in a given locality or jurisdiction.

L.A. Abrasion is a test that has been around a very long time and has accumulated a wealth of data that most designers can use and understand. The equipment is larger and more expensive than Micro-Deval, but it is also simple, reliable, and uncomplicated to operate. Modern designs make the equipment much safer, using enclosures to limit noise, dust, and hazards from moving parts. Before committing to either method, you should consider which test is most likely to be called for your projects.

What Equipment is Needed?

Our recommendation:

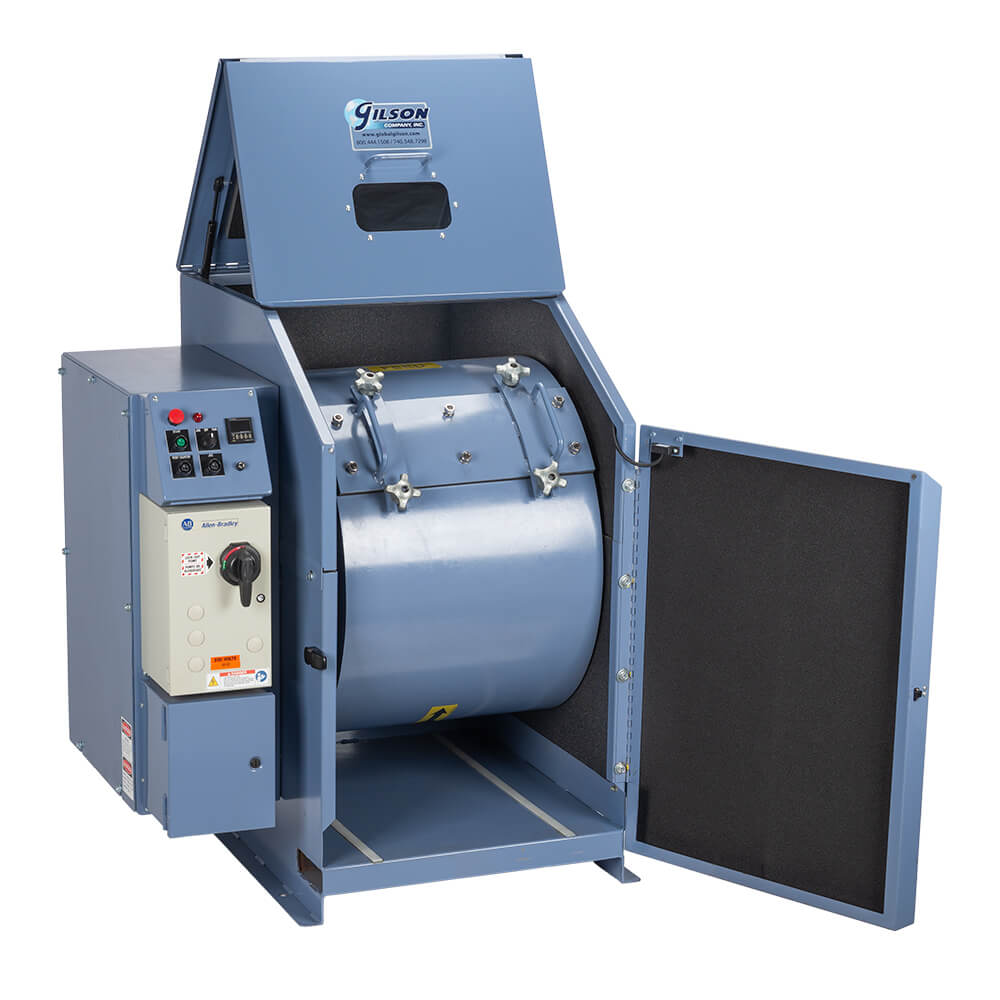

Gilson's Los Angeles Abrasion Machine which features:

- Fully-enclosed cabinet, covers all moving parts, prevents nuisance dust, and is lined with sound attenuating foam to reduce noise levels

- Electronic safety interlocks allow operation only with doors secured

- Powerful 1hp motor rotates the drum through an enclosed chain drive

- User controls mounted on the outside of the sound enclosure for straightforward operation

- ASTM-approved wide steel shelf to catch and drop the aggregate sample

- Controller stops revolutions after a preset number, and features overload protection

It’s important to remember that whatever method you choose, abrasion testing is a necessary procedure as part of a quality control process for gauging how materials will react to wear and tear over time.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)