Most materials have a lower size limit where sieving with a sieve shaker is no longer sufficient, and the agitation necessary for particle separation starts to break down and destroy some fragile materials. Particles in some substances resist separation and clump together due to electrostatic or moisture issues. For many years, these problems limited the effectiveness of measuring particle size by sieving. This article tells the story of how one man pushed back those boundaries.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Gilson Insights

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

Test sieves are an efficient, productive, and economical means of characterizing the gradation of dry granular materials. However, the sieving method is not without limitations. If obstacles seem to be making it difficult to produce accurate, repeatable results for finer sizes, Sonic Sieving may be the answer.

"…[Hydraulic] cement can't be characterized as just one material."

In this blog, we discuss what specifications define hydraulic cement and their use, as well as test methods and which testing equipment to use for your test application.

The selection of the best jaw crusher for your application will naturally be governed by the particle size, volume, and properties of your bulk material, along with the desired particle size and quantity of the final sample. In this blog, we help you select the right jaw crusher for your testing application.

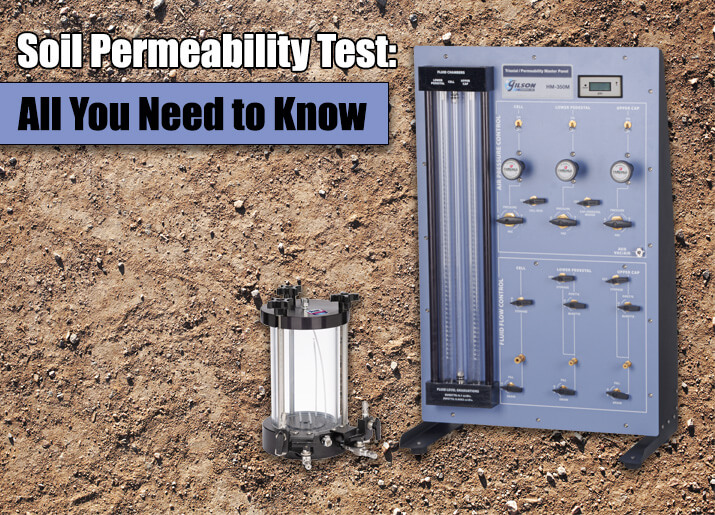

In this blog, we briefly discuss what soil permeability (hydraulic conductivity) is and detail what equipment can be used for a wide array of soil permeability tests.

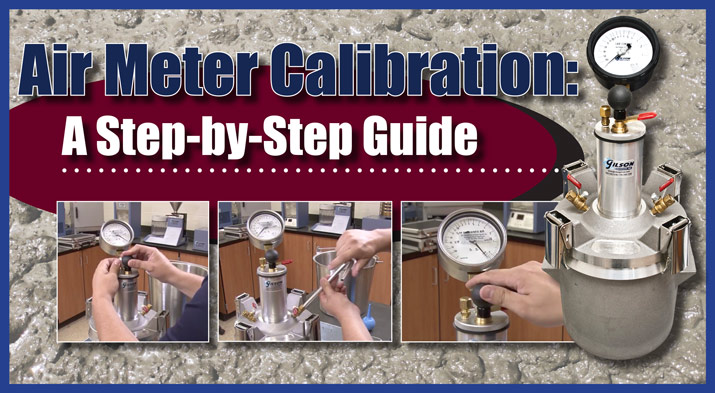

In this blog, concrete air meter calibration will be broken down into everyday language in such a way where the practice won't be tough to carry out and won't take long either.

Testing for air content is always recommended to profile characteristics of the admixtures in concrete. In this blog, we discuss what, why, and how to perform such test methods for concrete air testing.

Proper soil compaction increases strength and stability resulting in successful structures and pavements. This blog will discuss the various means of testing soil compaction, which methods are suitable for your project, and the importance of having the right personnel in place.

Maximum strength with minimum deformation. Get an in-depth look at how the Marshall method is used to attain optimum asphalt content.

Superpave’s origins came from simple questions that ballooned into complex, numerous offshoots as time passed and funding permitted. In this blog post, we discuss the impact of Superpave from the perspective of mix design, construction materials testing, and equipment for the lab.

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015