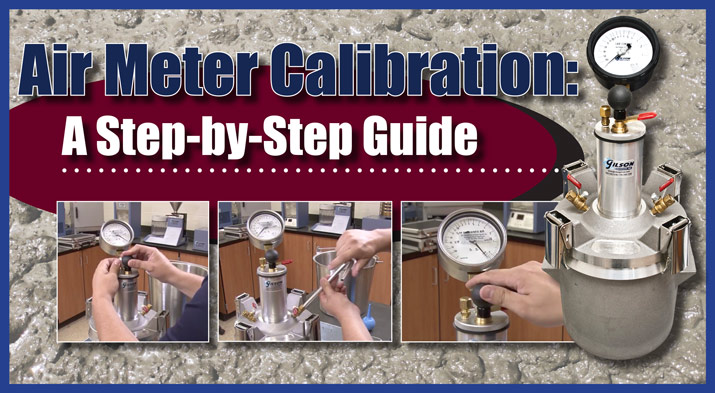

In this blog, concrete air meter calibration will be broken down into everyday language in such a way where the practice won't be tough to carry out and won't take long either.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Blog posts tagged with 'Field Testing'

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

Testing for air content is always recommended to profile characteristics of the admixtures in concrete. In this blog, we discuss what, why, and how to perform such test methods for concrete air testing.

Proper soil compaction increases strength and stability resulting in successful structures and pavements. This blog will discuss the various means of testing soil compaction, which methods are suitable for your project, and the importance of having the right personnel in place.

In this blog, we explore the two primary forms of soil classification for geotechnical purposes. Visual and laboratory classifications of soils are two distinct procedures that are part of a complete soils investigation.

This blog post discusses the differences between Liquid in Glass (LiG) mercury, LiG non-mercury, and digital thermometers used in laboratory materials testing. It also explores the role each type of thermometer plays in maintaining compliance with industry standards and regulations governing the use of mercury.

This infographic covers everything you need to know about the Super Air Meter (SAM) from what it is, the benefits, tips on how to use it, and more!

In part 3 of this three-part series, we’ll cover the procedure for effective particle size distribution of coarse aggregates, useful equipment and testing tips.

Concrete workability is used to describe how easily freshly mixed concrete can be mixed, placed, consolidated, and finished with minimal loss of homogeneity. Workability directly impacts the strength, quality, appearance, and cost of labor for placement and finishing operations. How can we measure workability? This blog post outlines everything you need to know about concrete workability, factors that can affect it, and helpful equipment and tests.

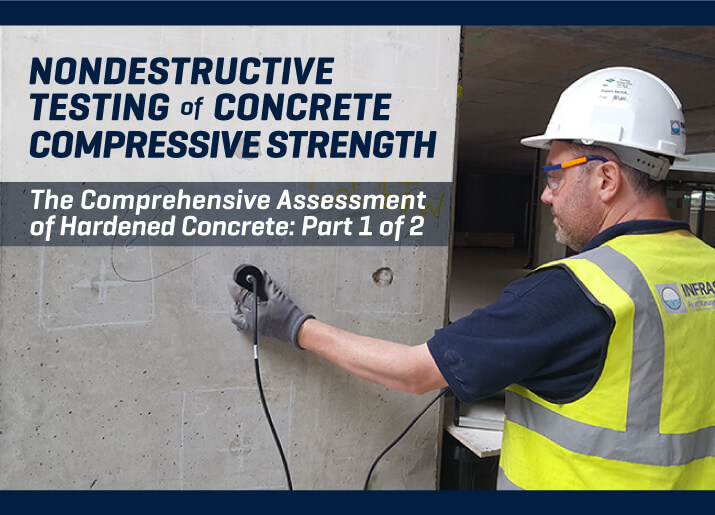

Nondestructive concrete testing determines the quality and properties of hardened concrete to assess its condition and safety. Read this blog to learn about in-place and nondestructive methods and equipment used to measure concrete strength.

In Part 1 of this thee-part series, we’ll cover sieve analysis of coarse aggregate, beginning from gathering samples at a job site, including tips and necessary equipment.

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015