There are specific properties of asphalt binder that influence pavement performance over the life cycle of a roadway. Binders classified according to their resistance to rutting, cracking, or other forces in very high or very low temperature environments allow the selective design of pavements with a long and cost-effective service life.

The importance of asphalt binders in the strength and durability of pavements led to the development of specialized tests and testing equipment to establish binder classification and grading. Older grading systems relied on penetration resistance or viscosity values combined with flash point, ductility, and solubility tests to classify the binder. Artificial aging with thin film ovens was later added to simulate conditions after production and paving operations.

Performance Grading: How Do Binders Really Behave?

In the late 1980s and early 1990s, the Federal Highway Administration (FHWA) initiated the SHRP and Superpave programs, which included a new binder classification system. The new Performance-Graded (PG) system was based on a series of laboratory tests demonstrating how the binders would perform over time in local or regional climate conditions. Designations for the binders reflect their optimum performance at maximum and minimum temperatures. Under this classification system, a PG 64-16 binder is ideal where local pavement temperatures do not normally exceed a maximum of 147.2°F (64°C) or fall below a minimum of 3.2°F (-16°C).

Most state agencies and modern testing labs have adopted or recognized the Performance-Graded binder classification system. In this blog post, we’ll present an overview of laboratory tests that focus on PG binders and discuss testing equipment. A previous Gilson Insights article Rheology and Viscosity Tests for Asphalt Binder: Methods and Equipment thoroughly explores the viscosity and rheology of asphalt binders.

Testing and Verifying Performance-Graded (PG) Binders

AASHTO M 320 and ASTM D6373 list binder performance grades and the test properties used to classify them. AASHTO Practice R 29 specifies a series of tests to verify the Performance Grade (PG) of asphalt binders based on the M 320 specification.

Samples suitable for PG classification testing must be free from water as determined by ASTM D95 and at least 99.0% soluble as determined by AASHTO T 44.

| Test | AASHTO Specification | ASTM Specifications | Testing Equipment | Acronym |

|---|---|---|---|---|

| Flash Point | T 48 | D92 | Cleveland Open Cup Testers | – |

| Short-Term Aging | T 240 | D2872 | Rolling Thin Film Ovens | RTFO |

| Flexural Creep Stiffness | T 313 | D6648 | Bending Beam Rheometers | BBR |

| Direct Tension | T 314 | – | – | DTT |

| Dynamic Shear | T 315 | D7175 | Dynamic Shear Rheometers | DSR |

| Rotational Viscosity | T 316 | D4402 | Rotational Viscometers | RV |

| Accelerated Aging | R 28 | D6521 | Pressure Aging Vessels Vacuum Degassing Ovens | PAV VDO |

Accurate PG classification allows better prediction of the long-term performance of asphalt pavement mix designs. There are a variety of test methods that measure asphalt binder performance. Many of the tests have lengthy names that are shortened to acronyms for convenience.

Flash Point testing describes the response of materials exposed to heat and a test flame under laboratory conditions. For testing with the Cleveland open cup device, a binder sample is heated at a specified rate in an open cup. When an open flame passed over the cup causes the vapor above the sample to flash, the specimen temperature is recorded as the flash point.

Short-Term Aging occurs during the mixing and placement of asphalt pavement. The Rolling Thin Film Oven (RTFO) simulates the aging of asphalt binders and measures the change in mass when volatile compounds are lost. Binder samples that have undergone short-term aging can be used for dynamic shear (DSR) and other tests to predict fatigue and rut resistance. The procedure also prepares samples for long-term aging in the Pressure Aging Vessel (PAV) and other tests requiring aged specimens.

Glass specimen bottles containing unaged liquid asphalt binder are held horizontally in a rotating carousel as a controlled flow of heated air is directed into the openings. The liquid asphalt film flows continuously as it is exposed to the heat, releasing volatile compounds and undergoing the aging process. More details of the RTFO equipment and test can be found in this Gilson Insights article Rolling Thin Film Oven Method for Evaluating Asphalt Binder Performance.

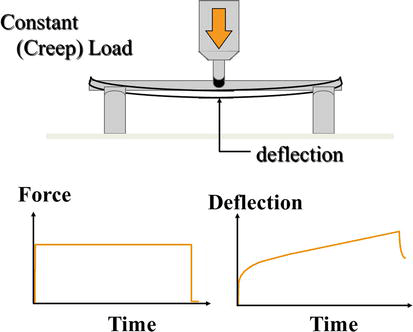

Flexural Creep Stiffness testing predicts the capacity of a binder to resist low-temperature thermal cracking when used in asphalt pavements. The Bending Beam Rheometer (BBR) loads an asphalt beam specimen immersed in a controlled-temperature fluid bath.

Liquid asphalt is poured into aluminum beam molds and cooled for demolding. When testing for compliance with Performance Grade requirements, bath temperatures from 0° to 32° to -32.8°F (-36°C) are selected from charts in AASHTO T 313 or ASTM D6648. The beam specimens are placed on supports in the cold fluid bath and loaded at mid-point. Two beams tested at specified loads for designated time intervals measure creep stiffness.

Direct Tension testing is used with BBR tests to gauge resistance to low-temperature cracking in asphalt pavements. The DTT method tests an asphalt sample in tension until it fails by brittle fracture.

A heated liquid binder is poured into a mold and bonded to phenolic mounting tabs on each end. The samples are cooled before testing in either an air-based cooling chamber or a fluid bath and cooled to a specified temperature between 21.2° and -32.8°F (-6° and -36°C). For testing, the prepared samples are mounted in a direct tension tester and pulled apart at a constant strain rate until failure occurs. The stress and strain rate at failure are recorded for subsequent calculations.

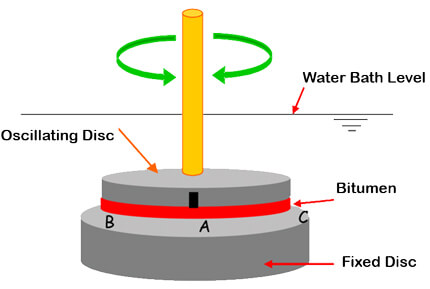

Dynamic Shear tests establish critical rheological properties of asphalt specimens. Depending on temperatures, asphalt binders can behave like elastic solids or viscous liquids. So, shear testing with the Dynamic Shear Rheometer (DSR) over a wide range of temperatures is critical for classifying PG binders. Test results are essential to effective mix designs that prevent future rutting and fatigue cracking in paving applications.

Small binder specimens prepared in silicone molds are mounted between two parallel plates in the temperature-controlled environmental chamber of the DSR. One of the plates oscillates horizontally at specified frequencies and amplitudes while precise torque measurements are recorded. For the AASHTO T 315 or ASTM D7175 test methods, aged or unaged samples are tested at temperatures from 39.2° to 190.4°F (4° to 88°C).

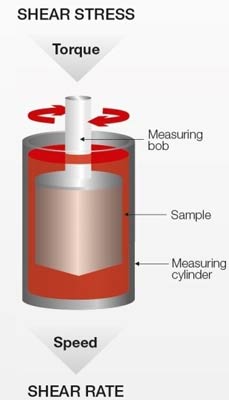

Rotational Viscosity tests measure the kinematic viscosity of binders at high temperatures encountered during the production, mixing, and laydown phases of asphalt production. These viscosity values are used in mix designs to estimate temperatures required for effective mixing and compaction operations.

The Rotational Viscometer (RV) measures the torque required to rotate a cylindrical spindle submerged in an asphalt binder specimen at a constant 20 rpm speed. The operating software in the RV converts the torque measurement to a kinematic viscosity value. Tests are typically conducted at a temperature of 275°F (135ºC).

Long-Term Aging methods for PG binder samples are necessary for accurate predictions of future pavement performance. Asphalt binder properties change over time in response to climate conditions and traffic loading cycles. Accelerated aging in the laboratory simulates the effects of aging and allows meaningful test results in a much shorter time.

Neither of the two following processes are tests. They are sample preparation methods for binder specimens that will undergo further laboratory testing with the bending beam rheometer (BBR), dynamic shear rheometer (DSR), or other instruments.

Pressure Aging Vessels (PAVs) continue the oxidative aging process started in the RTFO. Binder samples are subjected to an additional 20 hours of aging in a heated chamber pressurized to 2.10 MPa (305psi). The PAV accelerated aging process simulates 7 to –10 years of in-service aging.

Vacuum Degassing Ovens (VDOs) complete the long-term aging process started in the PAV. Binder material collected from the PAV pans is placed in the VDO chamber, heated to 170°C (338°F), and rapidly subjected to a vacuum of 15kPa absolute, forcing the release of entrapped air from the sample.

Additional Binder Tests

Other laboratory tests are often used to further define the qualities of PG and other asphalt binders. Some selected tests listed here characterize specific binder properties and help predict performance in pavement mix designs.

Ductility properties determine how well asphalt binders adapt to traffic loads and temperature changes in pavements. Low ductility binders tend to crack more over time.

For a simple ductility test following ASTM D113, a molded briquette of asphalt binder mounted in the water bath of a ductility tester is pulled apart at a controlled speed until the sample breaks. The total travel distance in centimeters is recorded as the ductility value.

The ASTM D6084 and AASHTO T 301 standard test methods measure the elastic recovery of the binder sample. This test uses a different briquette mold, and the sample elongation is stopped at a specified point. The sample is then cut in the middle and allowed to rest. After a specified time, the sample carriage of the ductility tester is reversed until the cut ends just touch. This distance is recorded as the elastic recovery.

Penetration tests are used in many applications for bituminous and other materials. For asphalt binder materials, ASTM D5 and AASHTO T 49 are the most frequently used test methods.

An asphalt binder sample is heated and then cooled to specified temperatures. A weighted penetration needle is positioned over the binder sample in a universal penetrometer, then released and allowed to penetrate the sample for a specified time. Penetration is measured to 0.1mm. A penetration depth of 8.0 mm would have a penetration value of 80.

Capillary Viscometers determine the viscosity of bitumen (asphalt binder) by measuring flow through a glass capillary tube at elevated temperatures. Viscosity is a measurement of the resistance to flow of a liquid.

Asphalt Institute Vacuum Viscometers determine dynamic viscosity in Poise units of measure following ASTM D2171 and AASHTO T 202 standard test methods. Absolute, or dynamic viscosity is the ratio between applied stress in the liquid and the shear rate. The test methods measure the time it takes to draw bitumen through a capillary tube under vacuum at 140°F (60°C).

Zeitfuchs® Cross-Arm Viscometers measure the kinematic viscosity of binders in Centistoke units following ASTM D2170 and AASHTO T 201 standard test methods. The kinematic viscosity of a liquid is the absolute (or dynamic) viscosity divided by the density of the liquid at the temperature of measurement. A temperature of 275°F (135°C) simulates the mixing and laydown temperatures typically encountered in asphalt pavement construction.

We hope this guide to tests and testing equipment has helped you understand Performance-Graded asphalt binders. Please contact our testing experts for questions or help with your application.

Additional Resources

Gilson Videos

- ATS Pressure Aging Vessel (PAV)

- Gilson Rolling Thin Film Oven (RTFO)

- ATS Rolling Thin Film Oven (RTFO)

- ATS Bending Beam Rheometers

Industry Links