Selecting the Right Sample Preparation Equipment

Gilson is pleased to announce the addition of Fritsch laboratory instruments to our comprehensive family of sample preparation equipment.

Headquartered in Idar-Oberstein, Germany, for over 100 years, Fritsch GmbH has earned its reputation as a respected manufacturer and supplier of high-quality laboratory equipment. Now in its fourth generation of family leadership, Fritsch specializes in the production of sample preparation, particle-size reduction, and particle-sizing instruments for laboratories worldwide.

Comminution, the particle-size reduction of materials by milling or grinding, is an essential step in the sample preparation phase of many laboratory tests. The ability to closely control final particle size is vital for meaningful test results and is frequently required in test method protocol.

Fritsch Means Better Design, Maximum Versatility & Optimum Performance

Fritsch design standards ensure versatility and ease of use are built into all their products. Cleaning and changeover of components is fast and easy by design and requires minimal or no tools. A full range of accessories supports each model to adapt the machines to a broad spectrum of applications.

Crushing jaws and disks, grinding bowls and balls, rotary cutters and knives, sieve inserts, and other accessories are available in various materials and designs to accommodate samples with different hardnesses, grinding characteristics, and testing requirements.

Additional accessories for individual models include support stands, optional feed and sample collection configurations, dust collectors, and automated vibratory feeders.

Send Us Your Sample

When you find a Fritsch product that appears to fit your application, Gilson wants you to be sure before you buy. Call or email our experienced Technical Support staff to discuss your application in detail. If there is a good match to a Fritsch product, we can test your sample at no charge and provide a complete report on our findings and suggestions. Simply answer a few questions beforehand, ship us your sample, and let us do the rest.

Laboratory Jaw Crushers

Jaw Crushers from Fritsch operate using a reciprocating plate or jaw of hard metal or ceramic material positioned at a shallow angle to a stationary jaw of similar material. Particles trapped between the jaws are fractured by force and pressure, moving by gravity to narrower areas between the plates to be fractured again. The crushing action continues until the particles are small enough to drop through the adjustable bottom opening.

These powerful machines are often used in the primary phase of size reduction to crush large particles of hard to very hard, brittle, tough materials like mineral aggregates, ores, recycled hardened concrete, or coarse-grained soils. Hardened steel crushing jaws are supplied with Fritsch jaw crushers. Jaws fabricated from tool steel, manganese steel, tungsten carbide, or zirconium oxide are available separately.

Fritsch Jaw Crushers feature fast, efficient crushing from feed sizes up to 2.4in (60mm) to a final mean particle size of 0.04–0.6in (1–15mm), depending on material type and machine settings. Maximum continuous throughput is 309lb (140kg) per hour.

Disk Mills

Disk mills feature two vertically mounted circular disks, one stationary and one rotating, to grind medium-sized particles of medium-hard to hard, brittle materials using pressure and shearing action. Adjustment of the gap between the two disks determines the final size. Aggregates, ores, ceramics, or construction materials are all suitable for grinding batch-wise or continuous operation in disk mills.

Fritsch Classic or Premium Disk Mills have a maximum feed size of up to 0.79in (20mm) and a maximum throughput of 331lb (150kg) per hour. The final size range is 0.004–0.47in (0.1–12mm) for Classic models and 0.002–0.47in (0.05–12mm) for Premium models. Grinding disks of hardened steel, tool steel, manganese steel, tungsten carbide, or zirconium oxide are sold separately.

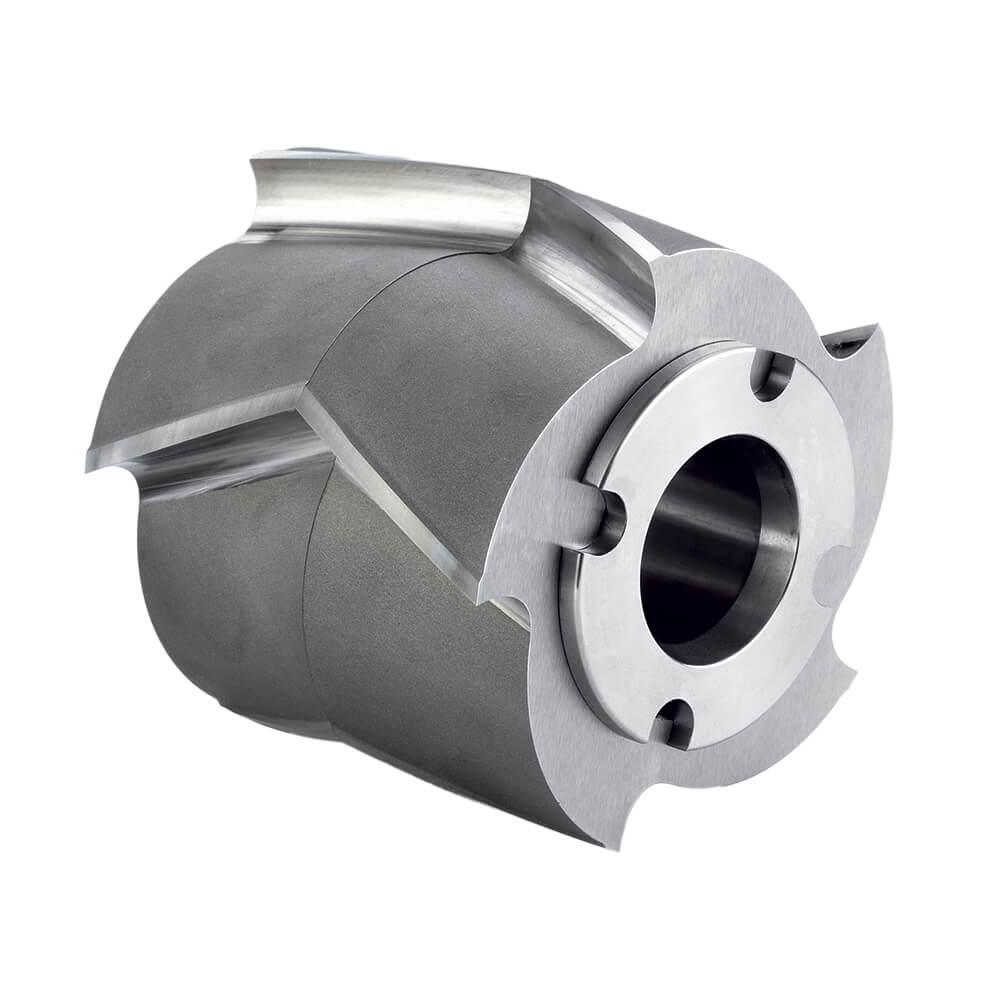

Cutting Mills

Soft to medium-hard, tough, and fibrous materials, including plant matter, plastics and textiles, foodstuffs, leather, circuit boards, and more, are quickly reduced in Fritsch cutting mills. These versatile mills shear materials fed through the funnel between a rotary cutting head and fixed knives. Elongated or irregularly shaped samples like fibers or plant stems can be fed directly into the mill without pre-cutting. The final size is controlled using interchangeable sieve inserts.

Fritsch Universal Cutting Mills are available in Standard or Large versions. Standard mills accept feed materials with dimensions up to 2.75x3.15in (70 x 80mm), WxD. Final fineness is 0.004–0.79in (0.1–20mm) depending on the sieve insert used. For Large mills, the maximum feed size is 4.7x3.35in (120x85mm), WxD and final fineness ranges from 0.01–0.79in (0.25–20mm).

Rotary cutters and stationary knives of different designs and materials customize the mills for various sample materials. Stainless steel sieve inserts feature a choice of square or trapezoidal perforated openings from 0.2–10.0mm. Sieve inserts with trapezoidal perforations improve efficiency when milling soft to medium-hard materials by adding an extra shearing interface for the rotary cutters. Cutting tools and sieve inserts are sold separately.

Cross Beater Mills

Continuous or batch-wise feed, variable speed, and robust construction make the Fritsch Cross Beater Mill ideal for the preparation or final grinding of medium-hard, brittle materials. The standard model is supplied with cast iron grinding components. A model with stainless steel contact surfaces is available for applications where iron contamination is a concern.

Comminution from impact, friction, and shearing takes place between the rotary cross beater arms and the grinding teeth around the circumference and on the side of the grinding chamber. Maximum feed size is 1in (25.4mm). Bottom sieve inserts with round or trapezoidal openings from 0.12–10mm control the final fineness of sample materials. A sample collection vessel with a 5L capacity is standard for batch-wise operation. An optional 30L plastic vessel is available for continuous feed applications.

Variable Speed Rotor Mill

The Variable Speed Rotor Mill by Fritsch performs high-speed grinding from 6,000 to 20,000rpm to process a variety of soft to medium-hard, brittle, and fibrous materials. This unit is ideal for final comminution after processing in cutting mills. Material fed through the top is impacted by the vertical ribs of the rotor and sheared against the ring sieves.

This benchtop unit has a compact footprint and features automatic speed regulation during operation for faster reduction of tough materials. An internal microcontroller regulates the optional Fritsch Vibratory Feeder for automated feed of granular materials.

The impact rotors are available with 8 ribs for fibrous material, 12 ribs for feed sizes less than 10mm, or 24 ribs for materials less than 5mm. Sieve rings with trapezoidal, square, or round openings are available in sizes from 0.003–0.24in (0.08–6mm). Maximum feed size is 0.39in (10mm). A final fineness of 40µm is possible, depending on the material and sieve ring size.

Knife Mill

The industrial-grade Fritsch Knife Mill is built for the fast reduction, milling, and mixing of soft to medium hard oily, fatty, moist, or fibrous samples like foods, plants, biological materials, or plastics. The four-bladed rotary knife works at 2,000–10,000rpm to reduce samples with feed sizes less than 1.6in (40mm). A turbo function with speeds of 14,000rpm can be activated for short periods.

Batch volumes up to 1.5qt (1.4L) are processed with final fineness ranging to <300µm in an average of only 30sec. The interior contours of the grinding vessel promote complete and efficient mixing of the sample. The controller is programmable with up to 20 automatic operating profiles for repeatable results.

All contact parts are autoclavable. Various optional grinding vessels, vessel lids, and cutting knives modify the cutting and mixing performance of the knife mill to optimize sample reduction and preparation.

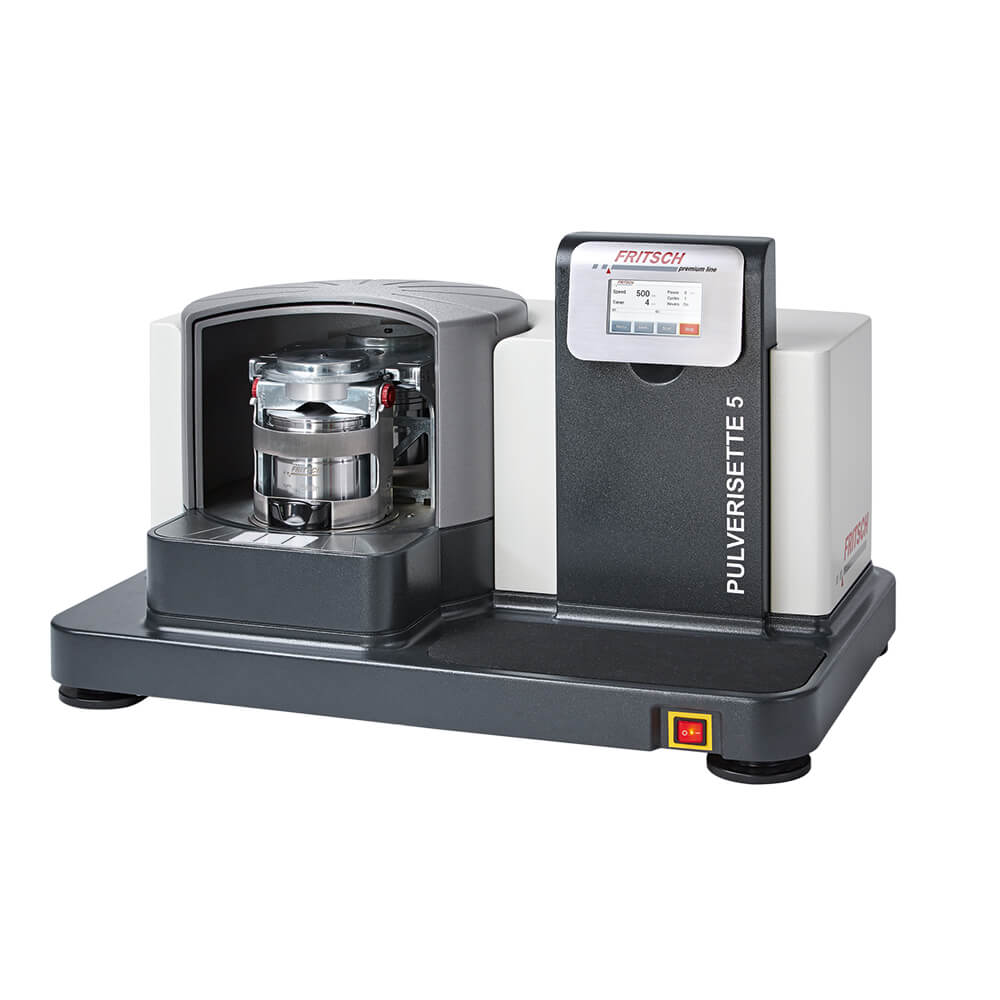

Planetary Ball Mills

Fritsch Planetary Ball Mills reduce small to medium batches of soft to hard, tough, and brittle materials in dry or wet conditions. Grinding bowls containing the sample material and balls rotate rapidly on their axis while mounted on a platform spinning in the opposite direction. The balls grind the sample during rotation until centrifugal force launches them across the bowl to impact material on the opposite side. This process works well for aggregates, minerals, ceramics, and biological, pharmaceutical, and other materials samples.

Classic planetary ball mills from Fritsch are offered with one, two, or four grinding stations and process samples with a feed size of 10mm to a final fineness of <1µm. The advanced two-station Premium Planetary Ball Mill for ultrafine grinding has additional safety features and can achieve a final fineness of <0.1µm, depending on the material. Reduction for most materials is complete in three to four minutes.

Grinding bowls of agate, sintered corundum, zirconium oxide, hardened stainless steel, or tungsten carbide are purchased separately in volumes from 80–500mL. Sample capacities range from 10–225mL, depending on sample types. Grinding balls made of the same materials as the bowls are sold separately in sizes from 0.6mm to 40mm.

Vibratory Micro Ball Mill

The Vibratory Micro Mill by Fritsch is a single-station ball mill that uses vibratory action to grind samples with a feed size of 5mm to a final fineness of 10µm. It is effective for dry or wet reduction and homogenizing medium-hard, brittle samples like aggregates, minerals, pharmaceuticals, or biological materials. The vibratory micro mill can be a cost-effective alternative to planetary mills for a limited number of applications and materials.

Grinding mortars (bowls) encased in protective aluminum are available in agate, sintered corundum, zirconium oxide, hardened stainless steel, or tungsten carbide materials and are purchased separately. 70mm grinding balls in the same materials and a 50mm agate ball are also available separately. Processing to final fineness is complete in about 10 minutes for most materials.

Mortar Grinder

Fritsch's Mortar Grinder is a modern, efficient, powered version of the mortar and pestle. Soft to hard materials that are brittle, fibrous, or tough are reduced and mixed in wet or dry conditions under pressure and friction from the adjustable pestle. The feed size is 8mm, and final fineness is 10–20µm. The mortar grinder accepts batch sizes from 10–190mL.

An adjustable scraper cleans material off the mortar walls and redirects it under the pestle during operation. Low-speed rotation of the mortar at 70–80rpm produces quiet, even processing with repeatable results and minimal heat gain. The mortar is encased in protective hard plastic to prevent damage. The grinding chamber is fully enclosed during operation, ensuring dust-free and low-loss grinding. Grinding progress is viewed through an acrylic window in the lid.

Mortar and pestle grinding sets in agate, sintered corundum, tungsten carbide, hardened steel, porcelain, zirconium oxide, and stainless steel ensure contamination-free grinding. Grinding sets are purchased separately.

Vibrating Cup Mill

Fritsch's Vibrating Cup Mill pulverizes hard, brittle, fibrous samples of materials like minerals, soils, glass, or ceramics. These mills, sometimes called puck mills or shatter boxes, use a fast, high-energy oscillating action to reduce materials using pressure, impact, and friction.

Wet or dry samples up to 250mL with a maximum feed size of 12mm are placed in a ring, along with a puck of hardened material, and secured in the mill. Rotational speeds from 600–1,500rpm, grinding times, and pause intervals are programmable for close control of grinding and precise repeatability. The final fineness of most materials ranges from 10–20µm.

Grinding sets are purchased separately in hardened stainless steel, tungsten carbide, agate, zirconium oxide, or chromium-free tool steel with 50, 100, or 250mL volumes.

Fritsch Crushers, Grinders, & Mills

| Description | Models | Maximum Feed Size | Final Fineness | Throughput1 | Applications | Reduction Principle |

|---|---|---|---|---|---|---|

| Jaw Crushers | FT-101 FT-103 | 2.4in (60mm) | 0.04–0.6in (1–15mm) | 309lb (140kg) | Hard to very hard brittle materials. Aggregates, ores, construction materials. | Fracture by force and pressure |

| Classic Disk Mill | FT-131 | 0.79in (20mm) | 0.004–0.47in (0.1–12mm) | 331lb (150kg) | Med-hard to hard brittle materials. Aggregates, ores, construction materials. | Force, pressure, and shearing |

| Premium Disk Mill | FT-132 | 0.79in (20mm) | 0.002–0.47in (0.05–12mm) | 331lb (150kg) | Med hard to hard brittle materials. Aggregates, ores, construction materials. | Force, pressure, and shearing |

| Universal Cutting Mill | FT-19 | 2.75x3.15in (70x80mm) | 0.004–0.79in (0.1–20mm) | 54.5qt (60L) | Soft to med-hard, brittle, tough, fibrous. Plastics, plants, foods, textiles. | Cutting and shearing |

| Large Universal Cutting Mill | FT-19L | 4.7x3.35in (120x85mm) | 0.01–0.79in (0.25–20mm) | 77.2qt (85L) | Soft to med-hard, brittle, tough, fibrous. Plastics, plants, foods, textiles. | Cutting and shearing |

| Cross Beater Mill, Cast Iron Grinding | FT-16 | 1in (25mm) | 0.005–0.39in (0.12–10mm) | 72.6qt (80L) | Med-hard, brittle materials up to Mohs 6 hardness. | Impact, friction, and shearing |

| Cross Beater Mill, St. Steel Grinding | FT-16V | 1in (25mm) | 0.005–0.39in (0.12–10mm) | 72.6qt (80L) | Med-hard, brittle materials up to Mohs 6 hardness. | Impact, friction, and shearing |

| Variable Speed Rotor Mill | FT-14 | 0.39in (10mm) | 0.003–0.24in (0.08–6mm) | 4.5qt (5L) | Soft to med-hard, brittle, fibrous, temperature-sensitive materials. Plastics, plants, foods, textiles. | Impact and shearing |

| Knife Mill | FT-11 | 1.6in (40mm) | <0.012in (<300µm) | 1.3qt (1.4L) ~30sec/Batch | Moist, oily, fatty, dry, soft, med-hard, fibrous. Food, animal feed, plants, biological. | Fast cutting, mixing, and grinding |

| Classic Planetary Ball Mill, 2-Station | FT-52 | 0.39in (10mm) | <0.00004in (<1µm) | 0.011–0.48qt (10–450mL) ~4min/Batch | Soft to hard, tough, brittle, dry to wet materials. Aggregates, minerals, biological, pharmaceutical, ceramics. | Impact, planetary, and grinding action |

| Classic Planetary Ball Mill, 4-Station | FT-54 | 0.39in (10mm) | <0.00004in (<1µm) | 0.011–0.95qt (10–900mL) ~4min/Batch | Soft to hard, tough, brittle, dry to wet materials. Aggregates, minerals, biological, pharmaceutical, ceramics. | Impact, planetary, and grinding action |

| Classic Planetary Ball Mill, 1-Station | FT-60 | 0.39in (10mm) | <0.00004in (<1µm) | 0.011–0.24qt (10–225mL) ~4min/Batch | Soft to hard, tough, brittle, dry to wet materials. Aggregates, minerals, biological, pharmaceutical, ceramics. | Impact, planetary, and grinding action |

| Premium Planetary Ball Mill, 2-Station | FT-50 | 0.39in (10mm) | <0.000004in (<0.1µm) | 0.016–0.48qt (15–450mL) ~3min/Batch | Soft to hard, tough, brittle, dry to wet materials. Aggregates, minerals, biological, pharmaceutical, ceramics. | Impact, planetary, and grinding action |

| Vibratory Micro Ball Mill 1-Station | FT-10 | 0.2in (5mm) | 0.0004in (10µm) | 0.011qt (10mL) ~10min/Batch | Med-hard, brittle materials. Dry to wet. Pharmaceuticals, biological, environmental, forensic. | Impact and vibratory grinding action |

| Mortar Grinder | FT-2 | 0.31in (8mm) | 0.0004–0.0008in (10–20µm) | 0.20qt (190mL) Per Batch2 | Soft to hard, brittle, fibrous, or tough materials. Wet or dry. Aggregates, minerals, biological, pharmaceutical, ceramics, abrasives. | Pressure and friction |

| Vibrating Cup Mill | FT-9 | 0.47in (12mm) | 0.0004–0.0008in (10–20µm) | 0.26qt (250mL) Per Batch2 | Hard, brittle, fibrous materials. Minerals, soils, glass, ceramics. | Pressure, impact, and friction |

1Throughput per hour for continuous feed or per batch for batch-wise operation. 2Time per batch is not rated.

Rotary Sample Divider

The Fritsch Rotary Cone Sample Divider is not a mill or grinder, but it still plays an essential part in sample preparation. Obtaining a test specimen that truly represents the bulk material can be elusive without the proper techniques and equipment. Rotary sample dividing is widely recognized as one of the most accurate representative sampling methods for wet or dry granular materials and suspensions.

Sample material fed into the top falls onto the point of a rotating cone. It disperses outward, flowing through a dividing head to a series of collection bottles mounted around the cone's perimeter. The divider produces eight, ten, or thirty identical subsamples. An optional vibratory feeder is ideal for dispensing granular samples into the divider.

Interchangeable dividing heads of polyoxymethylene (POM) plastic or aluminum with sampling ratios of 1:8, 1:10, or 1:30 and sample collection bottles with capacities from 15–500mL are sold separately.

Vibratory Feeder

The Fritsch Vibratory Feeder is an essential accessory that provides a controlled, automated flow of material to feed the Rotary Cone Sample Divider or the Variable Speed Rotor Mill. Uniform feeding of granular samples up to 10mm to either of these devices improves repeatability and ensures representative samples.

Material from the hopper/funnel is carried down the V-shaped stainless steel channel for consistent flow to the divider or mill. The control module features a timer function and adjusts the vibration amplitude to precisely control the flow rate of coarse or fine materials from 1–1,500g/min.

We hope you will keep Gilson and Fritsch in mind when selecting your sample preparation equipment. Please contact our testing experts to discuss your applications.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)